Everyone talks about how hotlamination is one of the most fascinating techniques in the printing world, but only a few actually know what it means, how it works, and what it is used for.

That is why we have written an article to reveal every backstory about this particular ennoblement.

WHAT DOES HOT LAMINATION MEAN?

In the printing industry, hot lamination is that process in which a fabric is laminated to a foil and through which a material is produced in multiple layers so that the combined physical and mechanical properties of each layer create a stronger and more durable composite material.

Lamination applied to the apparel industry is an operation by which a thin foil of metallized PES, called foil, can be transferred onto the surface of a fabric, previously printed with special adhesive resins, which adheres uniformly to the textile material and is distributed in a pattern.

HOW DOES THE HOT LAMINATION PROCESS TAKE PLACE?

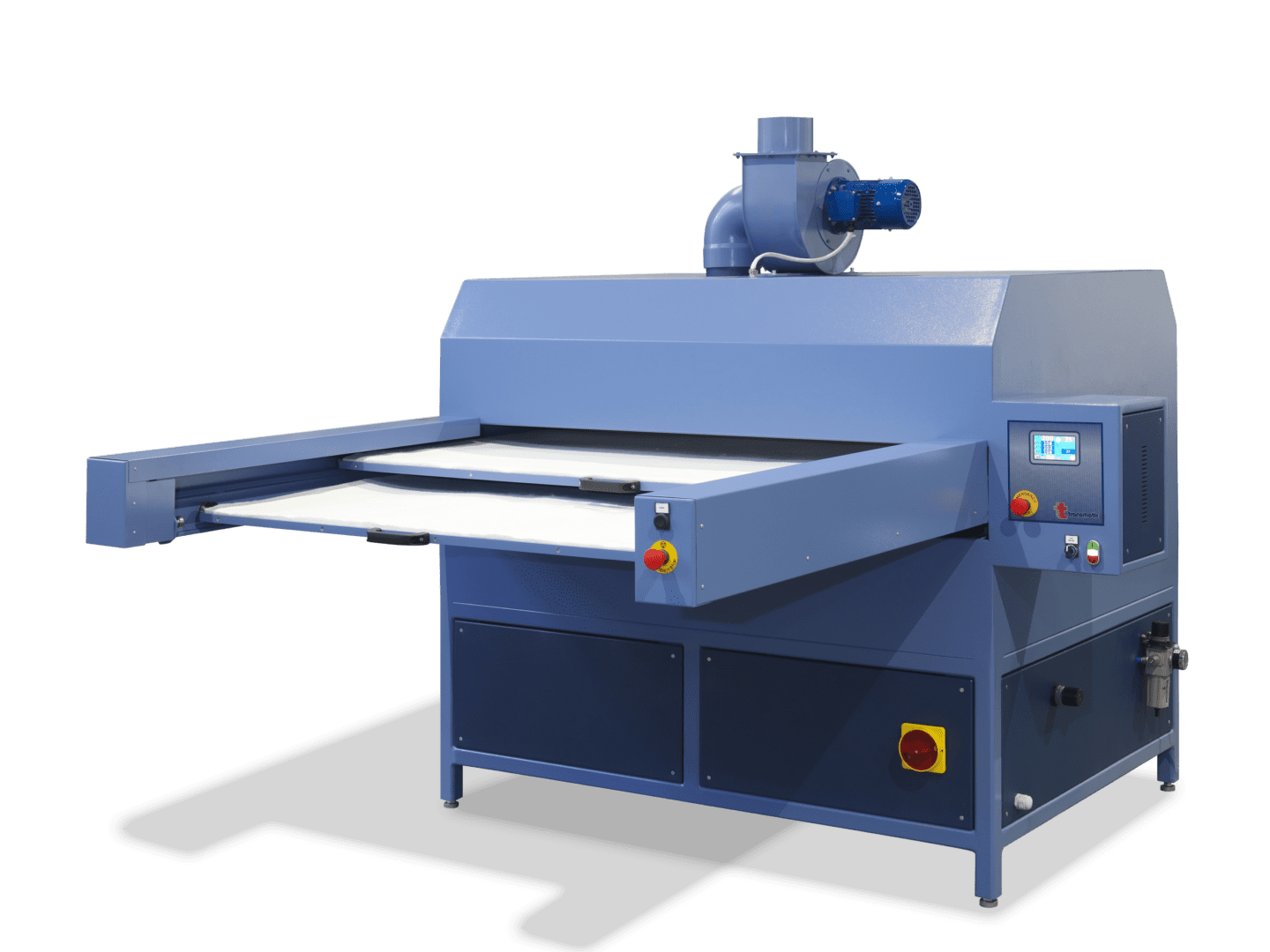

The process is done by a special machine that allows the foil to settle on the fabric.

Specific calanders capable of reaching high temperatures and pressures in excess of 40 tons are used during processing, allowing any fabric to be treated permanently and solidly.

This technique assumes the use of a foil, which is a special film that allows the image to be transferred to any type of material.

The foils that can be used for this processing are available in different metallic, pastel, holographic effect, and multicolor colors.

In practice, you first print the lettering, design or logo you want to apply using the screen printing technique, and then pass the foil with a hot press to imprint the color.

WHAT IS THE PURPOSE OF HOT LAMINATION?

Hot lamination is a technique used primarily in the textile industry as it allows a fabric to be ennobled, giving it new technical, physical, and aesthetic properties and making it suitable for different types of uses.

The fashion industry uses this particular ennoblement to embellish bags, shoes and small leather goods.

In addition, the numerous applications this technique offers also appeal to the home furnishings market.

Using heat-transferable films, lamination allows special effects such as lacquering, reptilian scales, sequins, crack, special paints and pull-ups to be applied to shuttle fabrics, knitted fabrics and continuous substrates.

Foils are used for decorating leather, faux leather, synthetics, and any type of fabric. In fact, it is possible to laminate both plain fabrics, paneled fabrics, and previously pleated fabrics, creating cutting-edge effects suited to the many needs of customers.

The process allows for different metallic effects in solid colors or printed in special patterns, allowing the user to give free rein to his or her creative flair.

SUPPORTS OF HOT LAMINATION: WHAT ARE THEY?

Hot lamination uses a variety of media to best enhance a fabric or object. These include lacquers, metal foils and acid films. Let’s see them in detail!

- Lacquers: lacquers are designs on polyester films that, by a hot calendering process, can be applied to fabrics, leather and faux leather.

- Metallic foils: foils allow the leather to be enhanced, characterizing it with an effect reminiscent of metals such as gold or silver. A collection designed to give uniqueness and beauty to the accessories on which it is applied.

- Acid films: these are highly versatile and technological films. Acid films can be applied to any genuine leather accessory. Their versatility and wide range of available designs allow their users to unleash style and creativity.

ADVANTAGES AND DISADVANTAGES OF HOT LAMINATION

The great advantage of hot lamination is the minimization of lead time without neglecting the metallic effect of handcrafted finishing.

A viable alternative to traditional hot foil printing is colored spot lamination, which combines perfectly with digital printing to enrich materials such as, for example, curtains, carpets, pillows, clothing, and much more.

The defect of hot lamination is foil detachment. In fact, the vast majority of the resins used are sensitive to alcohol, so contact with products such as perfumes, deodorants, lacquers, and stain removers should be avoided.

Did you find this article interesting? Follow us on our LinkedIn page to find out much more about the world of printing!