SERIGRAPHY

Screen printing is one of the most commonly used techniques in T-shirt printing services.

As a first step, the design to be made is broken down into primary colors using specific software. At this point the printing frames (one for each color) are developed and then placed on the screen printing carousel.

Finally, after the frames have been placed, printing begins on T-shirts, which are then subjected to an additional step in a special oven so that the inks attach to the fabric.

The advantage of screen printing is the fact that it is suitable for high dyeing, especially in the case of very simple designs. It is also very resistant to washing and can be made on any type of fabric with excellent results. Despite this, screen printing is uneconomical and therefore not recommended below a certain quantity.

DIRECT DIGITAL PRINTING

Direct digital printing is a T-shirt printing technique that arose recently and developed only in recent years.

The process is very similar to that carried out at home or in the office when printing text or images on paper foils.

The difference lies in the machines used, which, instead of printing on paper, print directly on fabric using special inks.

This technique allows any type of design to be printed and is also ideal for high-resolution photographic images. The positive aspect is flexibility in that it allows even a single piece to be printed at a reduced cost.

The disadvantage concerns wash resistance, which in the case of direct digital printing is lower than that of screen printing, and dark fabrics must be pretreated.

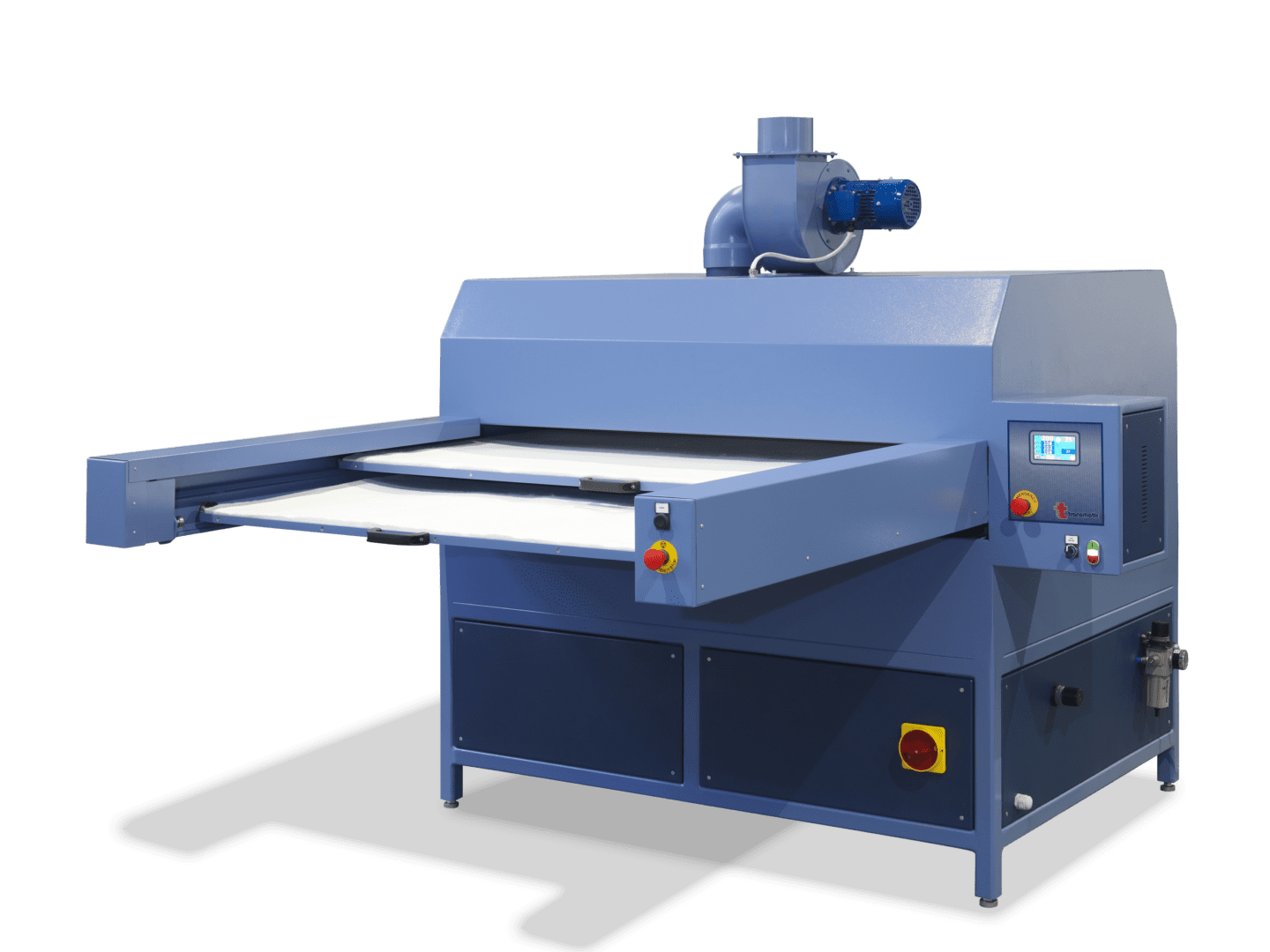

TRANSFER PRINTING

Transfer printing or thermoprinting is a fabric printing technique by which thermoadhesive films are etched through the use of a cutting plotter and then applied with the heat of a heat press to the fabric.

Transfer printing is able to offer a very high level of personalization to the chosen T-shirt or gadget, ensuring originality and high quality as the shades do not change during image transfer.

Thanks to the new techniques, the printing is also particularly durable and resistant over the years, so the printed images will not be damaged during washing or in contact with water or other weather conditions.

EMBROIDERY

Embroidery is a printing technique usually used to make small logos, and the result lends prestige and sophistication to any garment. In general, embroidery is used to customize T-shirts, uniforms, or professional clothing (hotels, restaurants, sailing clubs, etc.) with the aim of transferring added value to each garment.

SUBLIMATION PRINTING

Sublimation printing is a special printing technique mainly used to make prints all over the garment.

It is performed before the product assembly stage and immediately after the fabric cutting stage. Printing is done on a special paper using plotters loaded with special inks, called sublimation inks.

Then, using a heated calender, the printed paper is unrolled and laminated to the fabric to be printed.

On leaving the calender, the fabric will have absorbed the ink that was given to it by the paper due to temperature.

The result, in terms of color brilliance, is mind-blowing. It allows the entire garment and any kind of design to be printed, without any kind of limitation to shades, details or the like.

However, because it is a very expensive customization system, it must be implemented before the product is assembled. Can only be made on fabrics with a strong presence of polyester or synthetic materials in general.