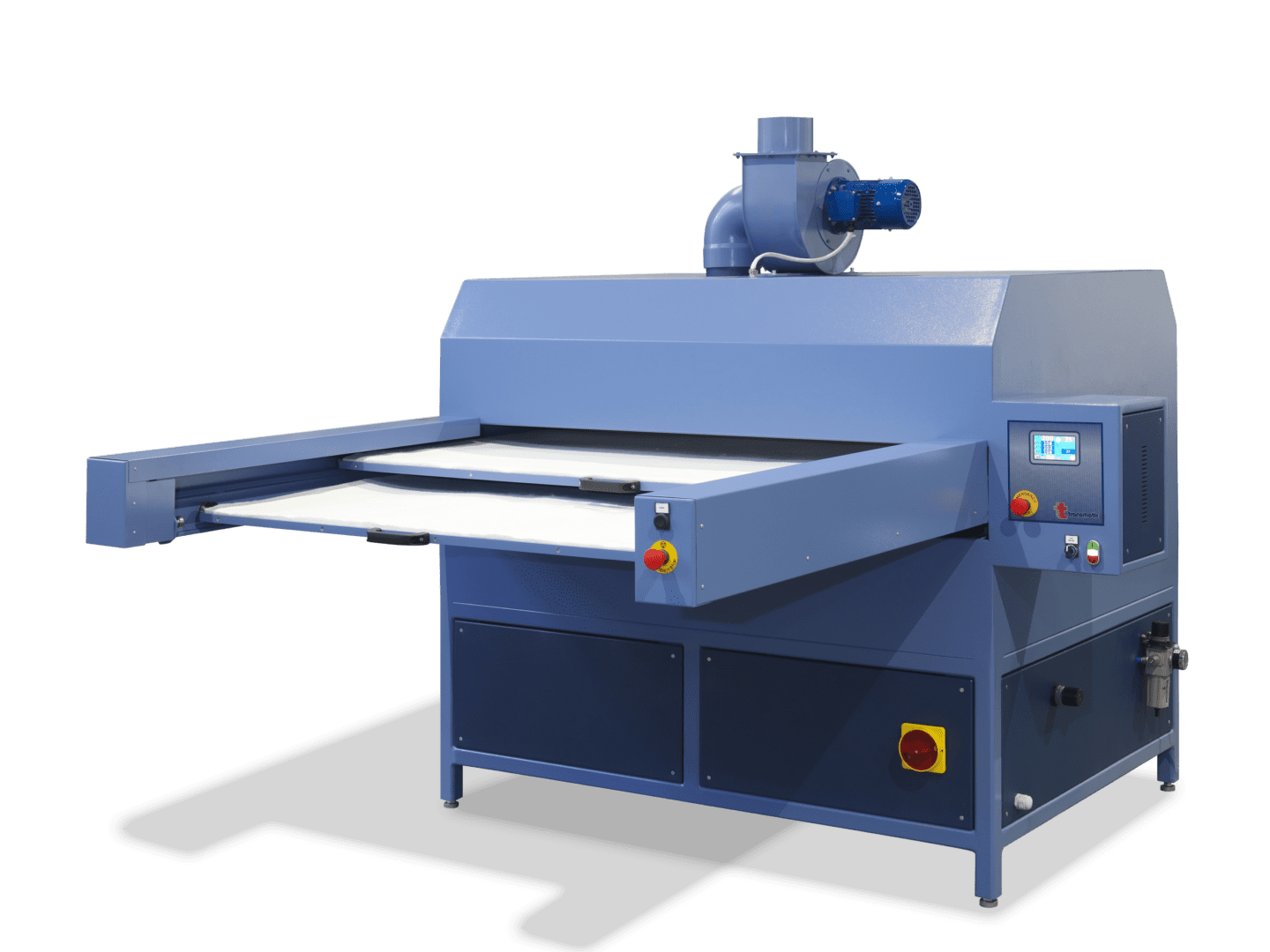

Designed for digital printing on cut pieces, placed prints, traditional roll-to-roll printing.

This application is especially suitable in the sports T-shirt printing industry. A new oil heating system ensures uniform temperature distribution over the entire length of the cylinder with minimal energy consumption. Transmatic’s oil heating systems consume 50% less energy than electric machines.nThe 65100 Sport has 3 different modes of operation.

1)The transfer papers are placed with the design facing upward on the table. Cut fabrics (fronts, backs, arms, necks, etc.) are placed on top of the pattern. The printed fabric pieces and paper leave the machine via a rear conveyor belt. 2)Use of roll transfer paper with the ability to place cut pieces of fabric.

3)Traditional printing of both transfer paper and fabrics in continuous.

Electropneumatic proportional dynamic felt control Ultralight aluminum expansion shafts.

Three friction-driven and three friction-driven and motorized rewinders.

Reversing safety bar.

n Automatic paper air separator.

n An outfeed conveyor cools and brings printed pieces to the back of the machine for detaching.

Automatic machine shut-off system after felt cooling Digital adjustable speed control.

Requires compressed air.