In recent times there has been a steady increase in the demand for and sale of digital printers for direct digital printing on textiles. Despite this, not everyone yet knows how to do flawless printing through a T-shirt printer. If you own a T-shirt printer, you will know that getting a perfect, professional result is not that simple.

That’s why we decided to take a closer look at the topic in this article where we’ll let you in on every secret about fabric printing and the importance of primers for fabrics .

WHAT IS A PRETREATMENT MACHINE?

A primer machine for digital direct-to-fabric printing is a tool for achieving quality prints even on dark fabrics. In fact, to have a professional printing result, it is necessary to prepare a fixing base for the colored inks. The latter, being water-based, are not opaque and because of their transparency are practically invisible on dark fabrics.

Therefore, the process of printing on dark fabrics to be sure of quality printing requires an extra step of first applying a white background to the fabric.

For light-colored garments, on the other hand, pretreatment is still advisable to improve color rendition and resistance to washing.

WHAT IS IT FOR?

As mentioned in the previous section, all colored fabrics require pretreatment first in order to be printed. Pretreatment is a process for white ink to cling to the fabric, without which it would be washed off in the first wash. This is a critically important step that prevents inks from mixing with fabric wetting colors.

For example, if you wanted to print a blue color on a yellow T-shirt, you would need to pre-treat the fabric to avoid getting a green color.

PRIMER MACHINE: WHY IS IT IMPORTANT FOR PRINTING ON DARK FABRICS?

A primer machine is essential for printing on dark fabrics. In fact, printing the white background requires pretreatment liquid, which is an adhesive that allows the white ink to attach to the fabric without risking being washed off later. This liquid, since it is a glue, should not be placed inside the printer because as you can imagine it would create serious damage to the machine. So it is necessary to have special machines that pre-treat the dyed fabric beforehand and separately.

HOW TO CHOOSE A PRIMER MACHINE?

Now that the importance of a pretreatment machine for dark fabrics is clear, let’s look in detail at how to choose one.

Here are 5 points to consider when choosing:

- Assess whether the pretreatment area of the machine is appropriate for your printer;

- Pay attention if the machine has an adequate system for collecting excess sprayed liquid, i.e., that which the fabric does not absorb;

- Check whether the nozzles can be taken apart easily to be cleaned daily;

- Consider whether the machine gives you full control over the area to be treated by allowing you to act only on the area targeted for printing and save pretreatment liquid;

- A very useful plus is the ability to select the volume of liquid emitted so as to speed up production and avoid too many steps.

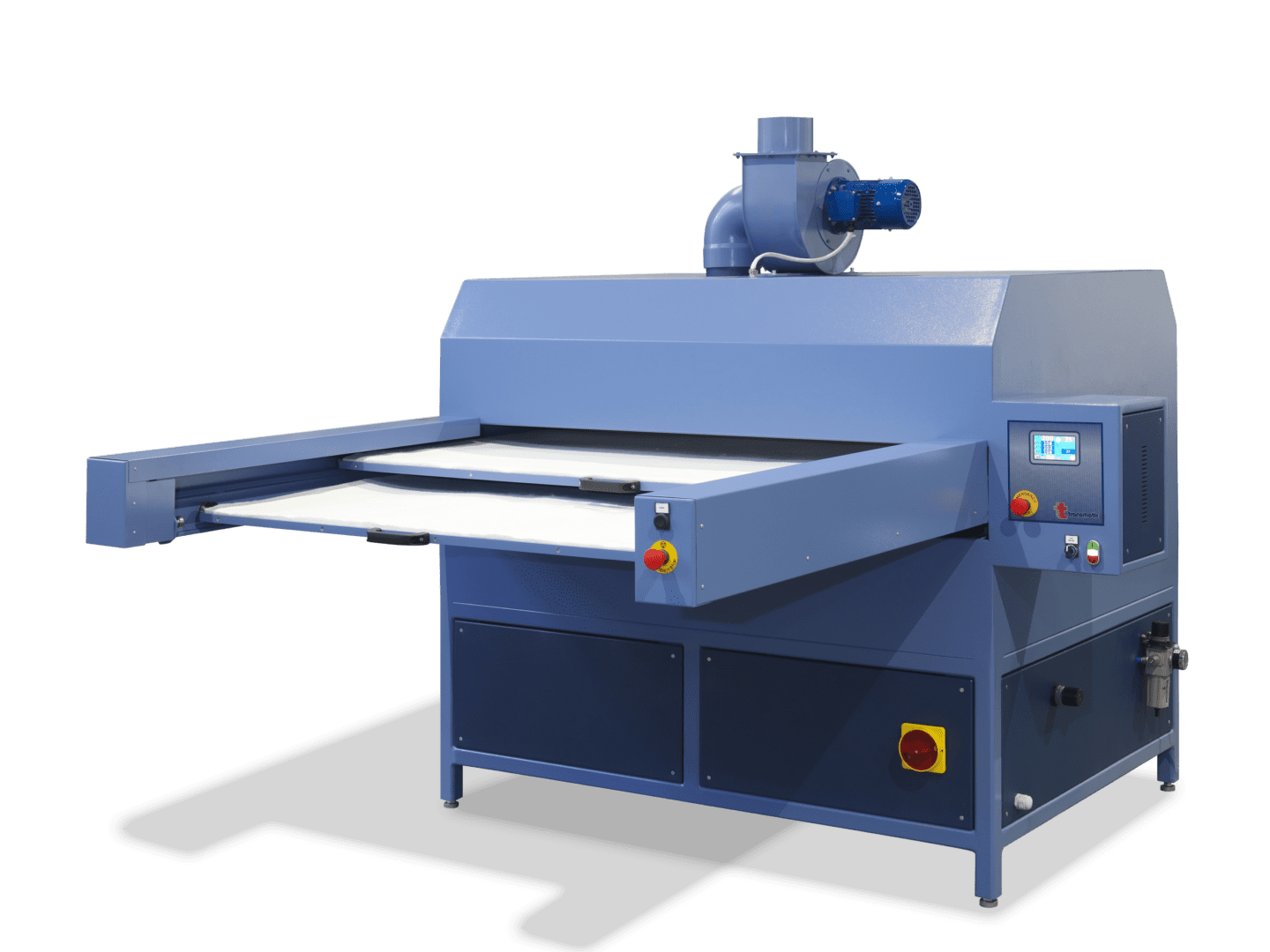

Discover the primer machine Transmatic PR-60 for pretreatment of fabrics intended for direct digital printing.

And if you found this article interesting, follow us on our LinkedIn page to find out much more about the world of printing!