sublimation printingIf you are in the printing industry, you have undoubtedly heard of sublimation printing, which, to date, is the most advanced and sophisticated technique for personalizing fabrics and surfaces.

In this article, we will look in detail at what sublimation printing is and delve especially into indirect sublimation printing, which is done through specific sublimation transfer papers.

WHAT IS SUBLIMATION PRINTING?

Sublimation, in the field of digital printing, is the process by which solid inks, when brought to high temperatures, are transformed into gases and permanently bonded to synthetic objects or fabrics.

In fact, sublimation printing or thermoprinting by sublimation represents a mode of printing that involves the transfer of thermosensitive sublimation inks that, upon contact with heat, permanently color the surface of the chosen product.

HOW DOES SUBLIMATION PRINTING WORK?

From a technical point of view, there are two sublimation printing methodologies: direct and indirect.

Indirect sublimation printing, which we will cover in the following article, is done by sublimation inkjet printers that transfer the color onto special transfer papers.

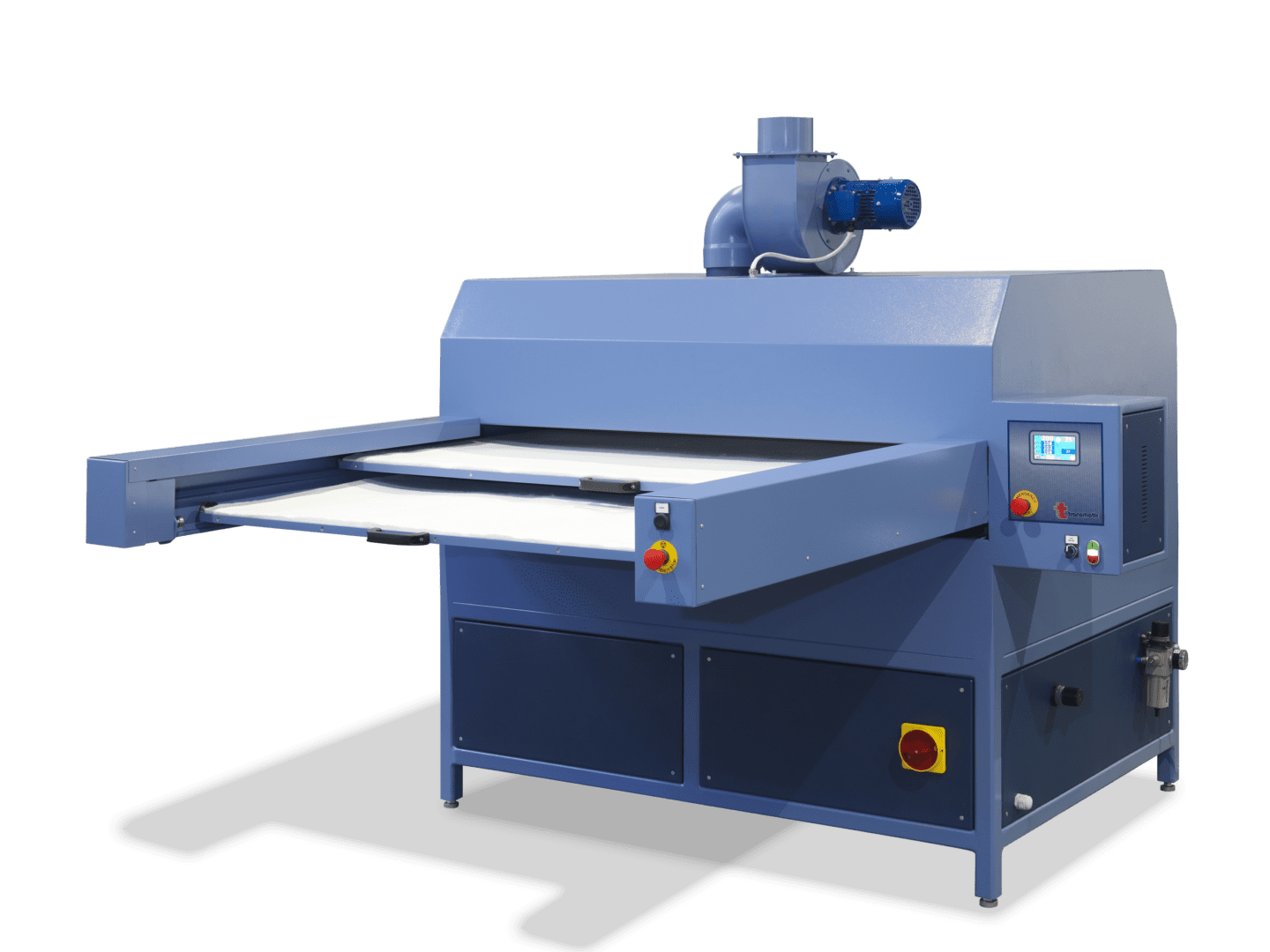

The latter absorb the ink and release it onto the receiving surface with a special press, called a heat press o sublimation calender .

Once the sublimation paper is placed on the fabric, it is hot-pressed (between 170°C and 210°C), thus generating a sublimation process of the ink, which from a solid state changes to a gaseous state and combines with the fiber permanently.

When this is finished, the layer to which the chosen image was applied is removed and waited for it to cool so that it can return to its original conformation.

There are three components that guarantee the required result: temperature, pressure and application time.

ON WHAT MATERIALS DOES SUBLIMATION PRINTING TAKE PLACE?

The sublimation is applicable to all synthetic fabrics, polyester, polyester-blend, spandex, microfiber, nylon, acrylic fabrics, TNT, and pretreated fabrics, as long as they are white or clear. On the other hand, it cannot be used on untreated cotton because natural fibers do not fuse with hot-melt inks. In addition, this printing mode can be exploited to customize any type of object that has acrylic components greater than 60 percent.

In fact, sublimation printing is generally used in textiles, flags, sportswear, and swimwear, but it is also popular in the world of customization of gifts and gadgets, as it allows high-definition images, photos, or text to be transferred to a wide range of surfaces (wood, glass, aluminum, ceramic, metal ).

WHAT CAN BE DONE WITH SUBLIMATION PRINTING?

Sublimation printing allows you to broaden your communication offerings to your customers by providing them with considerable variations in customization: advertising banners and ad hoc graphics for events, garments, furniture and interior design.

Sublimation printing on polyester allows for ultra-custom quality fabrics suitable for various sports categories (soccer, cycling, swimming, skiing, etc.) effectively conveying the colors, logos and advertising messages of sponsors.

In addition, thanks to its brilliant color rendering, solid blacks and prominent details, it is ideal in the making of garments for the fashion , guaranteeing final products of excellent quality.

In addition to fabric customization, sublimation printing is exploited on all kinds of gadgets and objects, as long as they have a sublimation-provided part. For example: surfboards, snowboards, sofas, tablecloths, bags, key chains, backpacks, cell phone covers, mugs, t-shirts, pennants, and more. All these applications therefore represent an attractive business opportunity for graphic designers, interior designers, printers, and printers.

ADVANTAGES AND LIMITATIONS OF SUBLIMATION PRINTING

Advantages of sublimation printing:

- Retention of fabric characteristics: by transferring color directly onto the fibers, sublimation printing does not alter the breathability, elasticity, and strength of fabrics, which will retain the properties of technical materials;

- Zero limits of creativity: like any desktop printer, it can transfer a wide range of colors and shades of digital design to the fabric, while maintaining very high resolution of colors and images;

- Long lasting and durable: the color is not subject to fading or scratching because the pigments that are transferred are not sensitive to UV rays and the coloring is permanent.

Limitations of sublimation printing:

- Material limitation: sublimation printing on 100% pure, untreated cotton is not applicable, as this is a natural fiber on which sublimation ink cannot fuse;

- Pigment transparency: sublimation printing on dark fabrics is not possible because there are no white sublimation inks. Transparent colors are used that absorb the hue of the background to which they are transferred and, therefore, are not applicable on black backgrounds.

Transmatic has established a deep experience in the hot stamping industry over time and offers a wide range of flat presses e calanders for indirect sublimation printing.

Thanks to the company’s skills and professionalism combined with continuous investment and constant research, Transmatic is now able to offer current and versatile products designed to fully meet every need.