WHAT ARE THEY?

Transfer printing on fabric is a new technique that became very popular especially in the 1970s.

Through it, the transfer of pattern motifs from a pre-printed paper substrate to fabric is achieved. This is an indirect printing process used for decorating fabrics and other materials.

Instead, direct digital printing on fabric is an innovative, high-quality technique that combines the superior technology of inkjet printers with screen printing inks developed and optimized for specific uses.

Direct digital printing is a technique used for customizing natural or synthetic fabrics and leathers such as cotton, polyester, or faux leather.

It provides prints with high-definition photographic rendering and soft to the touch as the color penetrates completely into the fabric.

HOW IS TRANSFER PRINTING DONE ON FABRIC? AND HOW ABOUT DIRECT DIGITAL PRINTING INSTEAD?

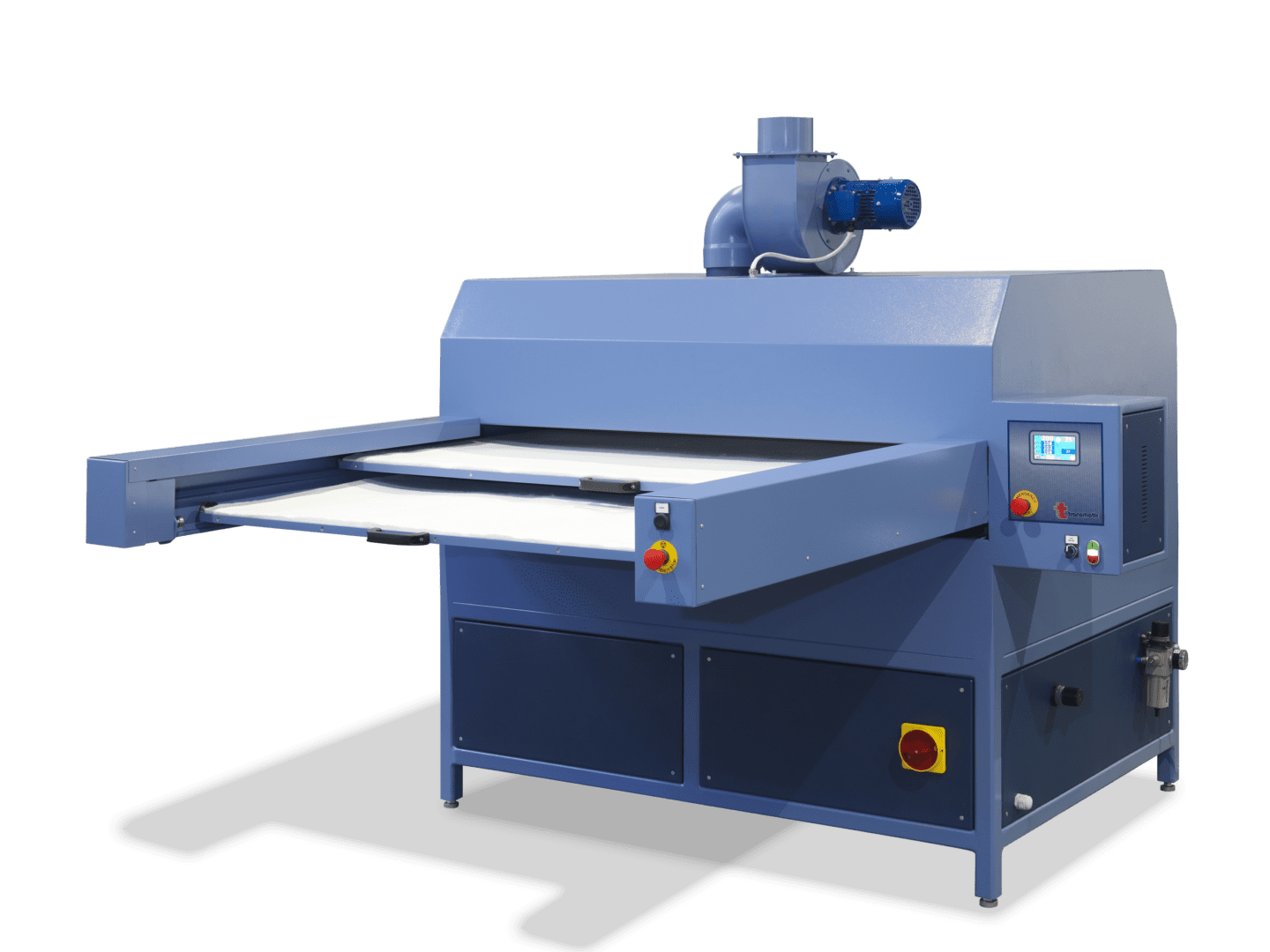

Transfer printing involves printing designs first on a special foil (called a transfer paper), and then transferring the print to the fabric through a hot press.

Through transfer printing, very different results can be achieved depending on the type of transfer, inks and printing technology used.

As for direct digital printing on fabric, however, images are printed in four-color or hexachrome on the fabric after applying a primer and through the use of an inkjet printer.

The pretreated fabric is placed on a special fixed stand, and the augelli, moving across the plane, draw the fabric as if it were paper.

The result is then passed through the oven and washed as appropriate for final fixing.

ADVANTAGES OF TRANSFER PRINTING ON FABRIC AND DIRECT DIGITAL PRINTING

Transfer printing on fabric can offer a very high level of personalization to the chosen T-shirt or gadget, ensuring originality and high quality as the shades do not change during image transfer.

Thanks to the new techniques, the printing is also particularly durable and resistant over the years, so the printed images will not be damaged during washing or in contact with water or other weather conditions.

Direct digital printing, on the other hand, is a technique that goes well with any fiber and is particularly suitable for decorating sheets, sweatshirts, jeans, towels and more.

The fact that you do not have to produce the screen-printed frame allows for short lead times and low costs. In addition, it guarantees very high quality for even the most complex photos and drawings thanks to the four-color process.

Other advantages include resistance over time to washing and friction, and the softness of the print due to the fact that the inks penetrate the interior of the fabrics, coloring the fibers.

Discover all Transmatic products related to transfer printing and direct digital printing!

And if you found this article interesting, follow us on our LinkedIn page to find out much more about the world of printing!